Gift Encyclopedia

Here are the latest information on corporate gifts, business gifts, exhibition gifts, seasonal gifts, and customized gift news.

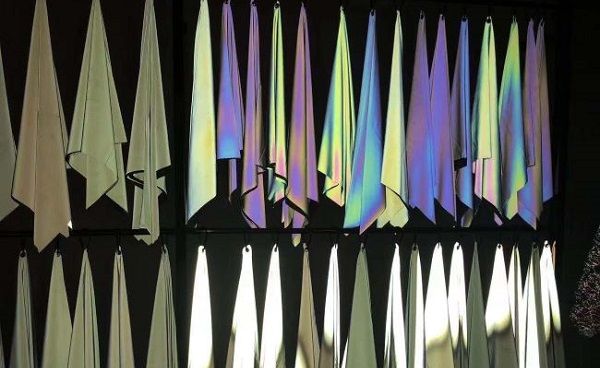

Clothing Reflective Print Technology: Silver Reflective Process Applications Guide

Fundamental Principles and Construction of Reflective Prints

Clothing reflective prints utilize specialized printing technology that applies materials containing microscopic glass beads or reflective particles onto fabric surfaces to achieve light reflection effects. This technology is widely used in nighttime safety clothing, sports equipment, and fashion design.

The core of reflective prints lies in their special structure, where light striking the surface with reflective material coating returns along the same path toward the light source, creating intense visual effects that effectively enhance visibility for wearers in low-light environments.

Characteristics of Silver Reflective Print Processes

Silver reflective print processes possess unique physical properties. First, they exhibit extremely high reflectivity, maintaining excellent visual effects under various lighting conditions. Second, silver reflective materials demonstrate superior weather resistance, withstanding erosion from ultraviolet rays, rain, and other natural factors.

In terms of hand feel, modern silver reflective print processes can achieve soft, conformable results without affecting garment comfort. Additionally, this process supports multiple pattern designs, enabling complex graphics and text effects.

Production Processes and Technical Requirements

Clothing reflective print production requires strict control of temperature, pressure, and time parameters. First, reflective materials are printed according to design patterns onto transfer films, then the patterns are transferred to target fabrics through thermal transfer printing technology.

Silver reflective print processes have specific requirements for base materials, typically suitable for common textile materials like cotton and polyester fibers. The production process must ensure reflective particles remain undamaged to maintain optimal reflection effects.

Practical Application Areas

In safety protection fields, reflective prints are widely applied to traffic police uniforms, engineering workwear, cycling equipment, and other products. These applications fully leverage the warning functions of reflective materials in nighttime or adverse weather conditions.

The fashion industry also extensively adopts reflective print technology, especially in nightclub clothing and street-style casual items, where silver reflective effects add unique visual appeal to products.

Quality Testing and Maintenance Guidelines

High-quality reflective print products should undergo professional reflectivity testing to ensure good performance at different angles. Simultaneously, washing fastness testing is required to verify that reflective properties remain after multiple washes.

Daily maintenance should avoid using strong detergents, recommending hand washing or gentle machine cycles, avoiding high-temperature ironing to extend the duration of reflective effects.

Future Development Trends

With increasing environmental awareness, water-based reflective materials are gradually becoming development priorities, reducing environmental impact while maintaining performance. Additionally, smart reflective technologies are under research and development, potentially achieving more advanced functional applications in the future.

Clothing reflective print technology is advancing toward higher safety, better comfort, and richer design options, providing better solutions across various industries.

- Latest Posts

-

Complete Guide to ID Card Holder Materials: Leather Metal Fabric Comparison and Durability Testing Analysis

2026-01-22 -

Hong Kong People's Favorite Lunar New Year Gifts: Traditional and Modern Fusion of Festive Greetings

2026-01-22 -

Hong Kong Eco-Friendly Gift Guide: Environmental Organization Collaborative Charity Products

2026-01-22 -

Complete Guide to Handmade Chinese New Year Gifts | Creative DIY New Year Gift Tutorial

2026-01-22 -

Kids Rain Gear Buying Guide: Safe & Comfortable Rain Equipment Recommendations

2026-01-22 -

Corporate Custom Umbrella Marketing Strategy: How Hong Kong Companies Build Brand Image Through Rain Gear

2026-01-22